Enhancing Security in Industrial Machining Workplaces

Within the fast-paced realm of commercial cutting and production, safety is a primary priority for organizations seeking to optimize their operations. With a variety of cutting technologies available, including laser and waterjet cutting service s, the potential for efficiency gains is substantial. Nonetheless, every cutting method comes with its own collection of risks that can impact both employees and machinery. Addressing these safety concerns is critical not only for compliance with regulations but also for creating a safe working space.

As sectors increasingly embrace cutting-edge cutting methods, it becomes crucial to implement measures that improve safety standards. Whether utilizing the precision of laser cutting or the versatility of waterjet cutting, recognizing the inherent risks and taking proactive steps can significantly reduce accidents and injuries. This article will discuss effective strategies, innovative solutions, and the latest technologies designed to ensure a more secure industrial cutting environment.

Summary of Cutting Methods

Commercial cutting plays a crucial role in production, offering precision and efficiency in the handling of various materials. Among the most notable methods are laser and water jet cutting services, each offering distinct features tailored to certain applications. Comprehending these technologies helps companies enhance their processes while ensuring elevated safety standards in the environment.

Laser cutting uses focused light to vaporize materials, attaining intricate shapes with superior accuracy. This technology is particularly effective on metal, synthetics, and composites, offering swift processing speeds and reduced kerf width. The ability to program detailed designs makes laser cutting a favored choice for industries requiring precise components. However, the intense heat generated can pose hazards if not managed appropriately, demanding strong safety procedures.

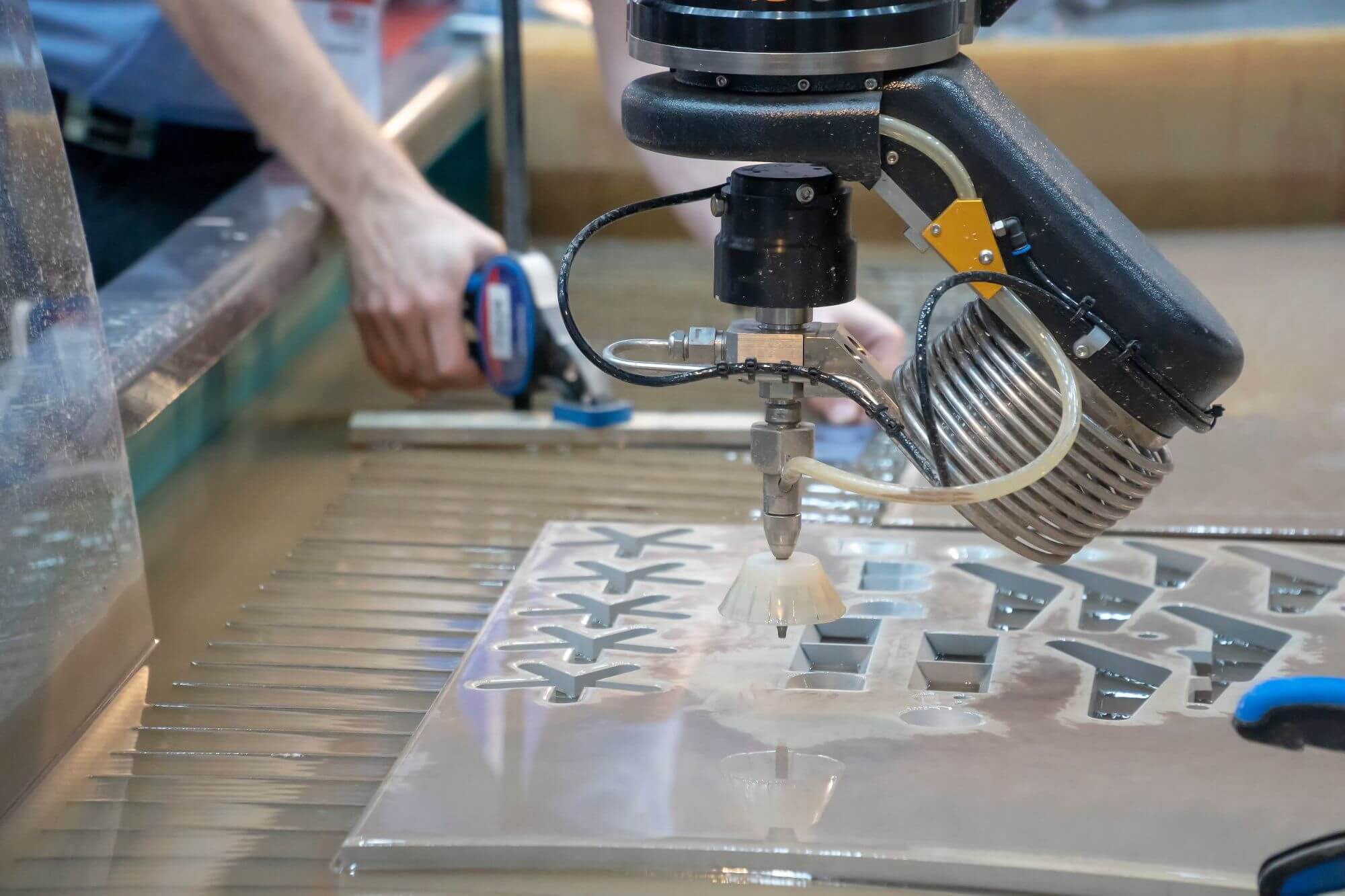

Waterjet cutting, on the contrary, uses a high-pressure flow of water, often mixed with abrasives, to slice through materials. This method is favorable for shaping thicker materials and those vulnerable to heat, as it eliminates thermal distortion. Water jet cutting processes are versatile, suitable to a wide range of materials including rock, glass, and metal. Despite its benefits, operators must be careful about water containment and fluid pressure management to maintain security in the cutting zone.

Security Protocols for Laser Cutting

When operating laser cutting equipment, it is essential to implement strict safety measures to protect personnel and equipment. First and foremost, all operators should receive thorough training on the specific laser system they will be using, focusing on its functions, potential hazards, and secure operating procedures. This training must encompass the identification of the risk factors such as laser exposure, fire hazards, and fumes generated during the cutting process. Moreover, all personnel should be aware with emergency shutdown procedures and the location of fire extinguishers and first aid kits.

Personal protective equipment is vital in a laser cutting environment. Operators must wear appropriate eyewear designed to protect against laser radiation, which is important for preventing eye injuries. Flame-resistant clothing and gloves can also reduce the risk of burns and other injuries, while ear protection may be necessary in environments with high noise levels. It is important to make certain that all PPE is well-maintained and readily available, as proper use can significantly reduce the likelihood of accidents happening.

Routine maintenance and inspections of laser cutting machines play a key role in enhancing safety. Operators should inspect equipment before each use to check for any signs of damage or malfunction, such as worn lenses, loose components, or insufficient ventilation systems. Implementing a routine maintenance schedule not only prolongs the life of the equipment but also guarantees that all safety features are functioning correctly. By focusing on maintenance, companies can reduce risks and create a more secure working environment for their employees.

Safety Measures for Water Jet Cutting

Effective protection protocols are vital in hydro jet cutting environments to safeguard operators and maintain a protected workspace. To begin with, making sure that every worker are properly educated in operating hydro jet machining machines is crucial. Training should cover not only the operation of the machines but also the associated hazards linked to high-pressure systems and the dangers of working near water and electricity. Exclusively trained and approved personnel should be allowed to operate the cutting equipment, reducing the risk of incidents.

Safety gear is another critical component of safety in water jet cutting processes. Personnel should utilize proper PPE such as safety glasses, hand protection, and auditory ear protection to safeguard against projectiles and excessive noise levels. It is additionally important to keep a neat and organized workspace to prevent trip hazards, trips, and accidents. Routine inspections and maintenance of the hydro jet machines are essential to ensure that all safety mechanisms are operational properly, and any leaks or problems are resolved promptly.

Lastly, establishing clear communication protocols among team members enhances safety in the cutting environment. Implementing a method for hand signals or verbal cues can help in coordinating operations, especially in a high-traffic setting. Additionally, having an emergency response plan in effect is vital. This procedure should outline procedures for dealing with incidents, equipment malfunction, or health crises, making sure that all personnel knows how to react promptly and efficiently in unforeseen events.